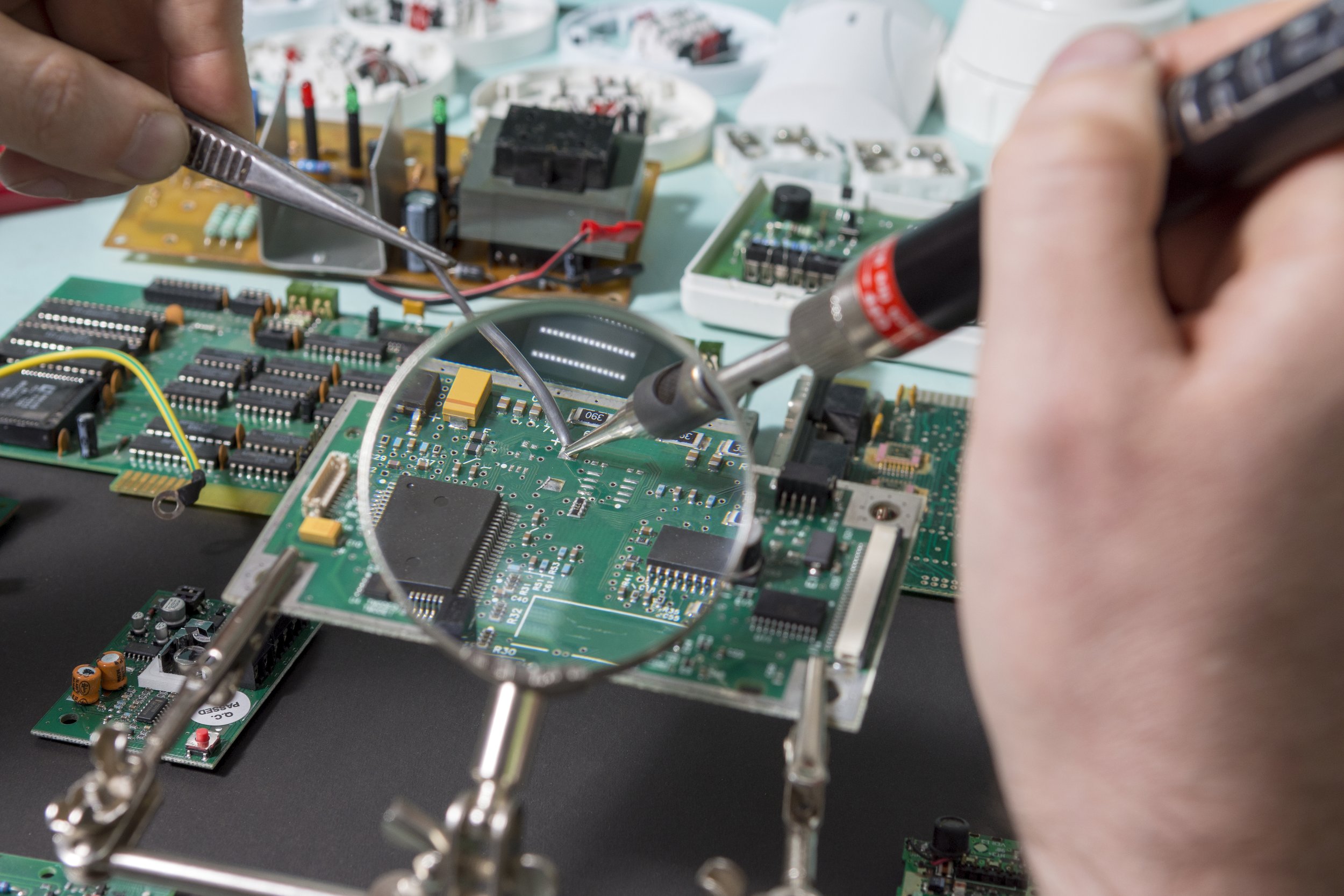

ADVANCED ASSEMBLY

Advanced Assembly means delivering end-to-end solutions that integrate scalable system development, turnkey product design, and operational excellence. WTS optimizes every stage—from collaborative engineering and rapid prototyping to process improvement and compliance—for efficient, high-quality product realization.

TECHNOLOGY SOLUTIONS

End-to-end development of scalable systems, software, hardware and customized platforms. Collaborative design optimization for manufacturability and cost-efficiency for existing products. From concepts, we develop schematic, layout, components selection, procurements to prototype build and develop testing for production to ensure 100% functional before shipment.

PRODUCT DESIGN & ENGINEERING

Newly branded product design from requirements and manufactured for specific customer needs. This turnkey approach lets our customers focus on innovation while we help to accelerate product launches, lowering cost and handling production complexities.

OPERATIONAL EXCELLENCE

Proven methodologies for process optimization and cost-reduction improvement. We kick off with a joint discovery workshop where design, supply chain and quality teams work side-by-side with our engineers. By co-creating the bill-of-materials, we balance cost, availability and compliance before the first board or system ever hits the production line. And provide DFx suggestions back to customers.

CAPABILITIES

PCB Assembly

Surface Mount Technology (SMT)

Through-Hole Technology (THT)

Mixed-Technology PCB layouts

Vietnam factory for production

U.S. for logistics and prototypes

Box-Build & System Integration

Cable and wire harness assembly

Enclosure fabrication and mechanical assembly

Final product integration and test

Prototyping & New Product Introduction (NPI)

Quick-turn prototype runs

Design for Test (DFT)

Design for Manufacturing (DFM) reviews

Pilot production and scale-up support

Testing & Quality Assurance

Automated optical inspection (AOI)

Functional testing

Environmental and burn-in testing

Supply Chain & Logistics

Turnkey material procurement.

Vendor management and component sourcing

Kitting, inventory management, and JIT delivery

Supplier audits and approval

Incoming Inspection (visual, dimensional, electrical)